Online association system

- Categories:Solution

- Time of issue:2021-09-27 10:36:14

- Views:0

1. The overall solution

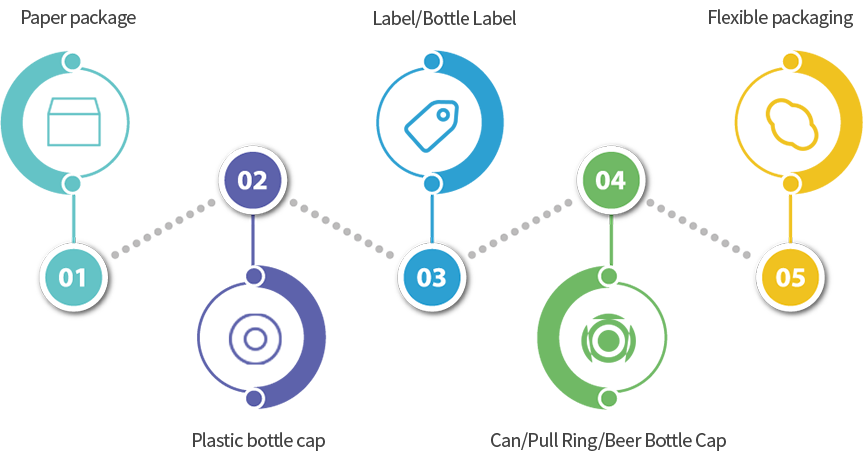

The packaging association of the production line is mainly to establish the corresponding relationship between the box code and the box code, and sometimes also involves the association of the box code and the pallet code. It can be applied to different packaging lines such as paper boxes, plastic packaging bags, plastic bottles, wine bottles, etc. We have different solutions for packaging lines in different environments.

2. Technical flow chart

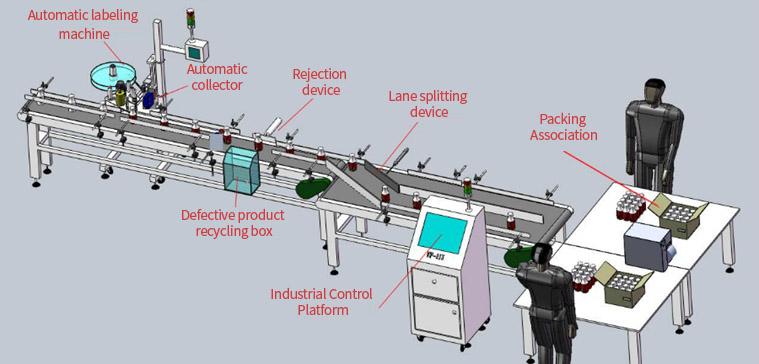

Step 1: automatic labeling, the personalized QR code label is affixed to the product through the automatic labeling machine.

Step 2: Automatic collection. Use a QR code and barcode reader on the assembly line to read the tag's QR code. If the tag's QR code cannot be read, it will be automatically rejected to avoid data confusion.

Step 3: automatic grouping. Qualified products are automatically grouped under system control to relieve packing pressure.

Step 4: automatic association. When the product reaches the packing quantity, manually scan the outer box QR code data (or automatically collect or automatically print the box label), and the system completes the bottle-box data association.

3. Associated software functions

A. Intelligent collection and association

① It occupies a small space, has a short reconstruction period, saves investment funds, and has the advantages of fast collection speed.

② Multi-level code assignment control can be realized, and the data association processing of all levels of code can be automatically processed.

③ Perfect seamless connection of upstream and downstream production lines.

④ Meet the normal coding requirements of production packaging, and automatically record the production date, batch number and other related information of each bottle of product.

⑤ Applicable to all bottled online labeling, coding and association, applicable industries; manufacturing, food, beverages and other industries.

⑥ Automatically count the production products and count the workload of the staff.

⑦ Centralized data management, which provides the main data for the direction anti-smuggling system.

⑧ On-site fault-tolerant mechanism. The packaging and coding production line is a system in which software and hardware cooperate and work together. The production line is relatively complex and works under high intensity. This system has implemented a thorough alarm mechanism and perfect fault tolerance for possible problems. Processing mechanism to ensure the normal and stable operation of the system.

Scan the QR code to read on your phone

Address: No. 5, Taiheng 3rd Road, Taiwanese Investment Zone, Haojiang District, Shantou City, Guangdong Province Tel:0754-88568333 Fax:0754-88525039 E-Mail:wang@kd315.com

CopyRight© 2021 Guangdong Zhengdi Technology Co., Ltd. 粤ICP备11006052号

0754-88568333

0754-88568333

wang@kd315.com

wang@kd315.com